Reason behind popularity

The reason behind the huge success rate of the manufactured crab trolleys is due to the use of the latest technology available in the market to produce the trolleys. Further, the kind of material used in the manufacturing of the trolleys is quality and standard. Moreover, the engineers and employees are very talented and have huge prior experience in this field that is why the firms come out with the best product.

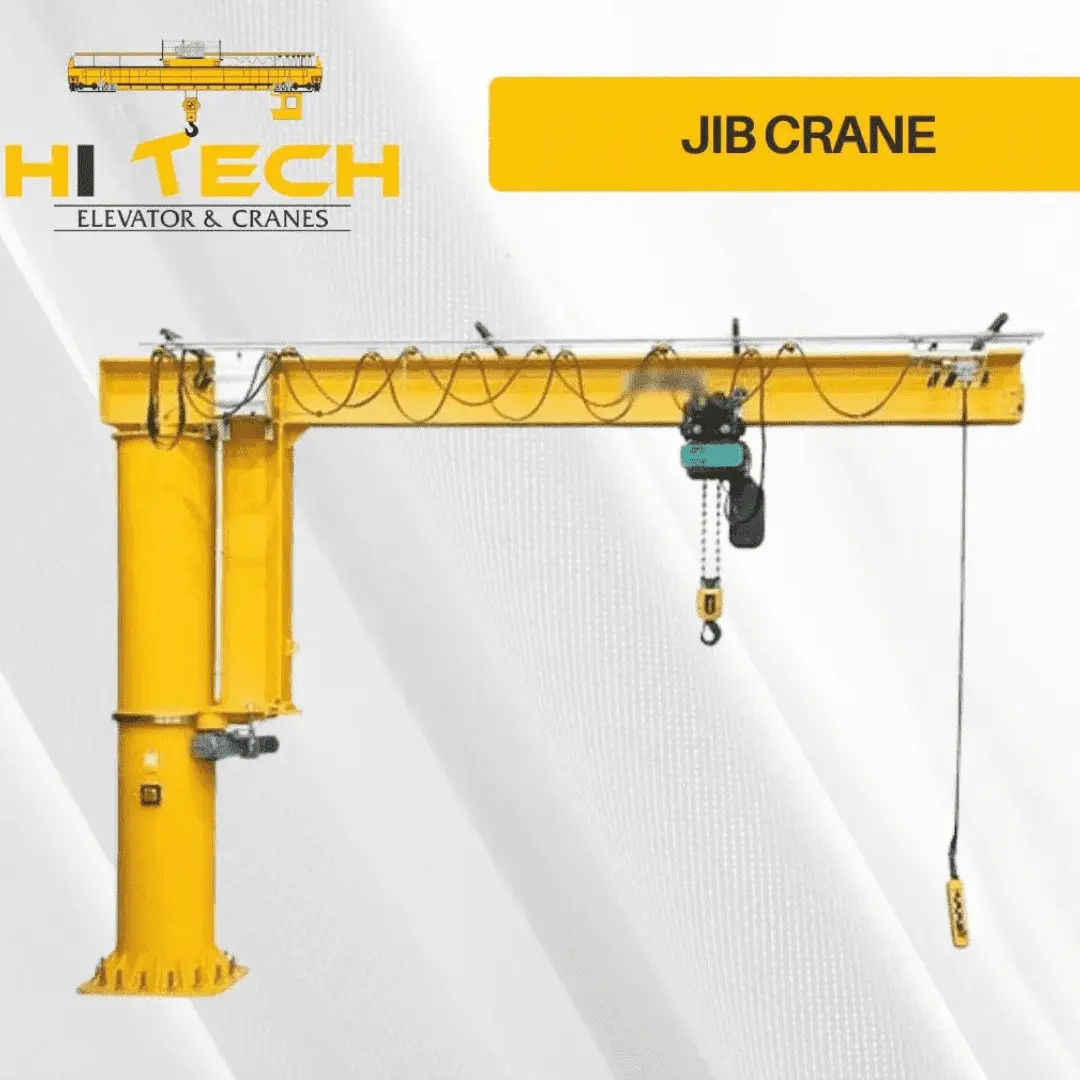

To take care of the vertical and horizontal loading along with the radial thrust, one needs to look for double roller self-aligned bearings which also have thrust and roller bearings in them. Swiveling is important to look at. With the help of the chain at the end of the jib arm and/ or hand cranking, Jib Crane causes easy swivel. Alternatively, one may also choose an electrically operated swivel embedded system. Fully insulated brass swing springs ensure a complete 360-degree rotation with pantograph current collectors provided.

Jib Crane are divided into two subcategories:-

-

Jib Crane with column: These have their main pillars fixed with the ground. These are usually used in industries to handle medium and low weights. Normal Jib Crane is expected to carry about 2000 kg. Hoisting in this case is done with chain hoist or electrical rope. It is possible to install motors for movement though by default it is manually operated.

-

Jib Crane at wall: These cranes are typically bounded to an existing structure such as the pillars or walls or columns. The operative characteristics are quite similar to a Jib Crane with column. These cranes are manufactured to meet the ISO standards

Look out for:-

- A certification for good quality to ensure safety and performance.

- A good arm length – usual case fall from 2 meters to 7 meters.

- A high hoisting capacity. While the general lies from 500 kg to 3000 kg when used in industries other Jib Crane used in ports can carry about 40 metric tons

- ISO certification for different parts used in the crane is important for a guarantee.

Features :-

- The Venus Jib Cranes are built to consistently high specifications conforming to IS 807 and 3177 most Fabricated from Pipe/Rolled Steel Steel Sections.

- M. S. Gusset plates/thick base plate giving added rigidity to column.

- Base plate readily drilled to take six/eight holding down bolts.

- Jib arm fabricated from heavy section I beam for SMJC-1 and triangular truss construction or SMJC-2&

SMJC-3type of jib cranes reduces deflection to acceptable limits.

- Bearings- Double roller self aligned type bearings with thrust &roller bearings to take care of horizontal

&vertical loadings as well as radial thrust.

- Swivelling -Through chain at the end of the jib arm and/or hand cranking for easy manual swivel,

alternately electrically operated swivelling for SMJC-3 type jib crane, on request.

- For positive full 360 degree rotation duly insulated brass swing springs with pantograph currentcollectors provided.

This typology of crane represents the ideal solution for the material handling, in the working area of the crane arm, in a specific workplace.The Jib cranes are divided in two categories:

Jib Crane with Collumn

- The jib cranes with column have the main pillar fixed on the ground.

- The jib crane for the industry is used to serve workplaces and handle materials with medium/low weight.

Normally up to 2000 kg.

- The hoisting is realized with an electrical rope or chain hoist.

- The trasversal movements (through the jib arm and its rotation) are done manually by the operator; is possible install motors for the both movements.

Jib Crane at Wall

- This cranes are bounded to an existing structure (columns, pillars, walls, etc). The operative characteristics

are same of the jib cranes for industry..

- The Bonfanti's cranes are developed and produced in the respect of the ISO 9001 norms (TUV).

The main features are :

- CE certification.

- Hoisting capacity: from 500 to 3000 Kg (jib crane for industry); up to 40 metric ton (jib crane for ports).

- Crane Arm length: from 2 to 7 meters (standard). Other dimensions are done on specific request.